We understand the complexities involved in wiring and our iMCCs follow IEC/IS classification for various types of wiring and their definition.

“iMCCs Switchboards have the flexibility to store relevant motor data in the PLC and motor control device thus allowing retention of data during failure” “The well deployed as per the application and process, the intelligent MCC allows users to monitor and analyse operations from anywhere at any time”

The History & Progression of a MCC to an iMCC

Conventionally, MCCs started its journey with only Electromechanical components that included basic systems like overload prevention, short-circuit protection, power switching and indication state of controller with the hardwired connections in place. These kinds of MCCs are still running in the industries with over half of the equipment containing electromechanical devices.

The advancement in the technology brought Solid-state components, where the devices can be programmed instead of just switching a motor ‘on’ or ‘off’. It was further followed by a series of programmable logic controllers (PLC), starters and drives where the integration was done by hardwiring to an I/O module. Later, it was the advent of advanced monitoring systems with Network components with simplified wiring. However, there occurred certain limitations like failure to bifurcate the communication and power lines, flexibility of architecture and troubleshooting the initial network connections with the MCC devices.

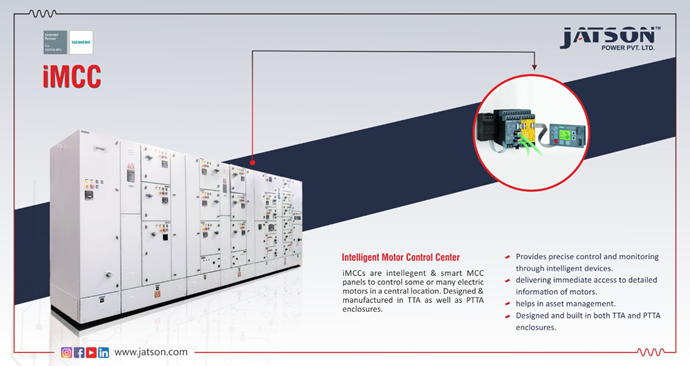

These challenges have led to a next generation Intelligent Motor Control Centre (iMCC) with the integration of three main categories such as MCC monitoring software, hardware control components and in-built communication source. A standard MCC needed inter wiring and testing before implementation. But an integrated iMCC comes with pre-installed communication cables, pre-tested, pre-programmed and pre-configured software screens. With the lower installation cost and improved productivity, the iMCCs has laid the foundation for improved manufacturing efficiency with reduced downtime.

The iMCC developed by different switchgear technology companies available today have been designed on the basis of applications such as Oil &Gas, Mining, Pulp &Paper, Chemicals, Utility and Waste water. These iMCCs are manufactured to serve for a range of applications and sticking to the most stringent industrial standards at the same time. iMCCs have the flexibility to store relevant motor data in the PLC and motor control device thus allowing retention of data during failure. When properly deployed, the intelligent MCC allows users to monitor and analyse operations from anywhere at any time.

Now, iMCC – Why are they Intelligent?

iMCCs are designed in such a way as to deliver real time data monitoring that plays a major role in control schemes to enhance productivity and optimize critical asset availability. These systems provide an opportunity for the equipment manufacturers to use and analyse the process data in order to streamline the productivity. Component manufacturers have developed software that helps to generate real-time data, graphical representation, status indication by maximizing the performance of MCC. They also ensured that advancement in Low-Voltage MCC help reduce Arc-Flash hazards by minimizing risks. Arc-Flash is the result of sudden electrical explosion due to the excess voltage in the bus. Further, the use built-in networking and pre-configured software is the significant features in iMCC technology. Moreover, iMCCs provide the data that can be utilized to simplify wiring and reduce the cost, reduce downtime and establishing interface for constant monitoring. While logically comparing an iMCC to a standard MCC, what actually differentiates an iMCC is wiring. This gives it an edge over the inter wired MCC (along with chassis).

Author

Baljinder Singh (BE- Electrical)

Baljinder Singh (BE- Electrical)

About the author- Baljinder Singh is working with Jatson Power Pvt Ltd, Vapi as Business Head. With years of experience in manufacturing of electrical switchboards and switchgear components is a seasoned professional. Proficient with excellent communication skills he is always up with the industry trends and product innovations helps industry end users to choose the right electrical solutions.

2 Comments

Ujash Patel

Nice blog

Akash Patel

Good information!