About Us

JEM: Excellence in Sheet Metal Fabrication and Powder Coating

JEM is a cutting-edge facility located in Umbergaon, specializing in delivering comprehensive solutions for sheet metal fabrication and powder coating. Our commitment to quality and innovation is reflected in every step of our manufacturing process, supported by state-of-the-art technology and an expert team.

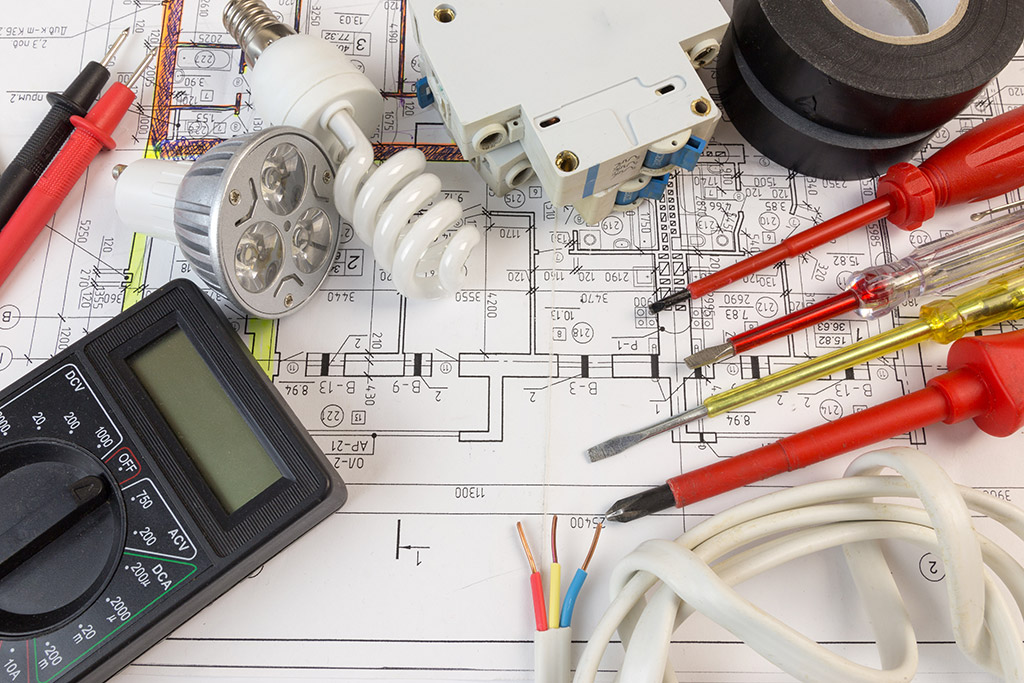

Advanced Technology for Precision Manufacturing

State-of-the-Art Equipment

JEM boasts a laser punching machine of the highest caliber, paired with a computerized numerical controlled (CNC) bending machine. These advanced tools enable us to achieve unmatched precision and quality in fabrication, meeting even the most stringent requirements of our clients.

Nine-Tank Surface Treatment Plant

Our nine-tank surface treatment process ensures complete grease and rust removal, providing a clean, corrosion-resistant surface. The process includes zinc passivation, a critical step for enhancing durability and extending the lifespan of fabricated products.

Conveyorized Powder Coating Plant

The facility features a conveyorized powder coating plant that ensures uniform application, resulting in a flawless, long-lasting finish. This automated system delivers exceptional paint adhesion and finish quality, meeting industry standards.

State-of-the-Art Equipment

JEM boasts a laser punching machine of the highest caliber, paired with a computerized numerical controlled (CNC) bending machine. These advanced tools enable us to achieve unmatched precision and quality in fabrication, meeting even the most stringent requirements of our clients.

Nine-Tank Surface Treatment Plant

Our nine-tank surface treatment process ensures complete grease and rust removal, providing a clean, corrosion-resistant surface. The process includes zinc passivation, a critical step for enhancing durability and extending the lifespan of fabricated products.

Conveyorized Powder Coating Plant

The facility features a conveyorized powder coating plant that ensures uniform application, resulting in a flawless, long-lasting finish. This automated system delivers exceptional paint adhesion and finish quality, meeting industry standards.

Commitment to Quality

At JEM, quality is our cornerstone. To maintain superior standards, we have implemented:

Stringent Quality Control

Using advanced quality check instruments, we ensure that every product undergoes rigorous inspection to meet established parameters. This guarantees that all items leaving our facility adhere to the highest industry benchmarks.

Set Standards and Procedures

Well-defined operational procedures and quality metrics are followed diligently to deliver consistent and reliable results.

Skilled Workforce

Behind JEM’s success is a dedicated and highly experienced team. Each professional is specialized in their respective operations, ensuring seamless execution of tasks. From fabrication to finishing, our team ensures:

- Timely delivery of projects without compromising quality.

- Error-free execution, minimizing wastage and maximizing efficiency.

WHY CHOOSE JEM?

Integrated Solutions

From initial fabrication to the final powder coating, JEM offers a one-stop solution for all your sheet metal needs.

Expert Team

A skilled workforce with extensive experience in the field.

Advanced Infrastructure

Cutting-edge technology and equipment for superior quality and precision.

Commitment to Excellence

Stringent quality controls to meet and exceed customer expectations.

At JEM, we do more than fabricate metal; we build trust through quality, innovation, and timely delivery.